Choke balun 1:1 OM0AMR

Pri (born)regular cleaning of the hamshack, I came across one ferrite core, which I once gutted at the OM3WSG tent from VN transformer from the old TV (it almost fell on my leg from the closet) and in addition to the mention of all the saints, I immediately wondered what to do with him. I decided for the so-called. choke Wonderful article 1:1.

Because the ferrite core is quite massive, it is also suitable for larger performances. The main limitation for the power load was the use of a suitable coaxial cable. At home I had a choice of RG316, RG58 mil C 17, RG8MINI, it's hard to fix something like this remotely 213, RG214 mil c 17 a BELDEN H1000. Since rg316 and rg 58 transfer approx 600 W a RG 213, 214 a h 1000 they are too shapeless for this purpose, I used rg8 mini which seamlessly transfers 1kw. The balun is supposed to be mainly on the 160m band, so I wound it on it 2x 6 threads coax.

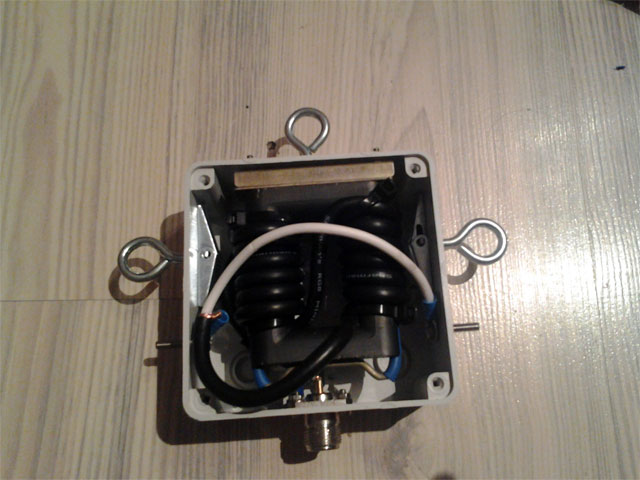

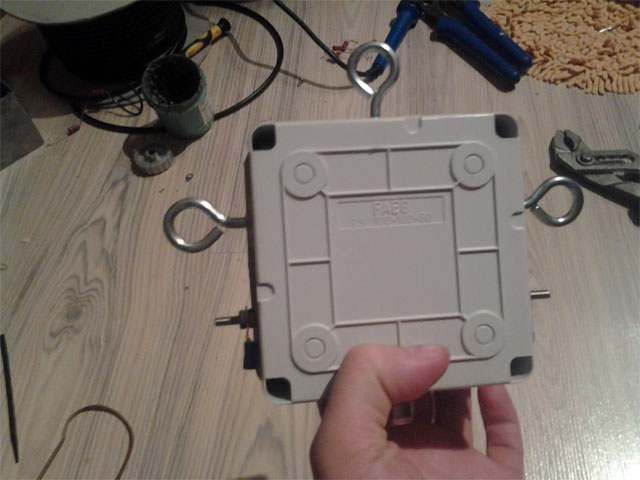

Plastic box, connector, eyelets and stainless steel screws I had at home, so I had no problem with the material, so to speak. Measurement and drilling took only a few minutes. I screwed the ferrite core to the box and measured the exact lengths of the coax ends, and gradually I soldered the eyelets and the connector to the ends of the coax. (in my case N connector, because I have finished coaxes on the roof with just N connectors).

Gradually, I put it all in the box and tightened all the nuts and nuts. At the end I still measured the balun multimetrom (if there is no short circuit) and sealed the contacts on the screws and connectors with hot melt glue to prevent water from condensing into the coax. Then I just drilled a 2mm hole on the bottom of the box to allow condensed water to drain from the box. (even if it is waterproof), he put the upper part and tightened the screws properly. The entire production of the balun took approx 25 minutes.

Rado OM0AMR